Activator built Pigxcel, an AI-powered image-analysis platform for pig producers, using the ABP Framework to deliver a secure, scalable multi-tenant SaaS solution. By leveraging ABP’s built-in multi-tenancy, modular architecture, and rapid development capabilities, the team was able to launch quickly while keeping costs low and customer data fully isolated. Today, Pigxcel helps farms worldwide optimize slaughter-weight accuracy, reduce feed waste, lower manual workload, and improve animal welfare — all supported by an architecture designed to scale as the customer base grows.

Activator set out to build Pigxcel as a scalable SaaS platform for pig producers, but the team faced a key technical challenge: supporting multiple customers with completely isolated data while keeping the solution cost-efficient and future-proof. They needed a reliable multi-tenant architecture that could handle growing data volumes, package features across subscription tiers, and scale geographically as adoption increased. At the same time, the team wanted to accelerate development speed without sacrificing security, maintainability, or performance — a balance that can be difficult to achieve in AI-driven platforms.

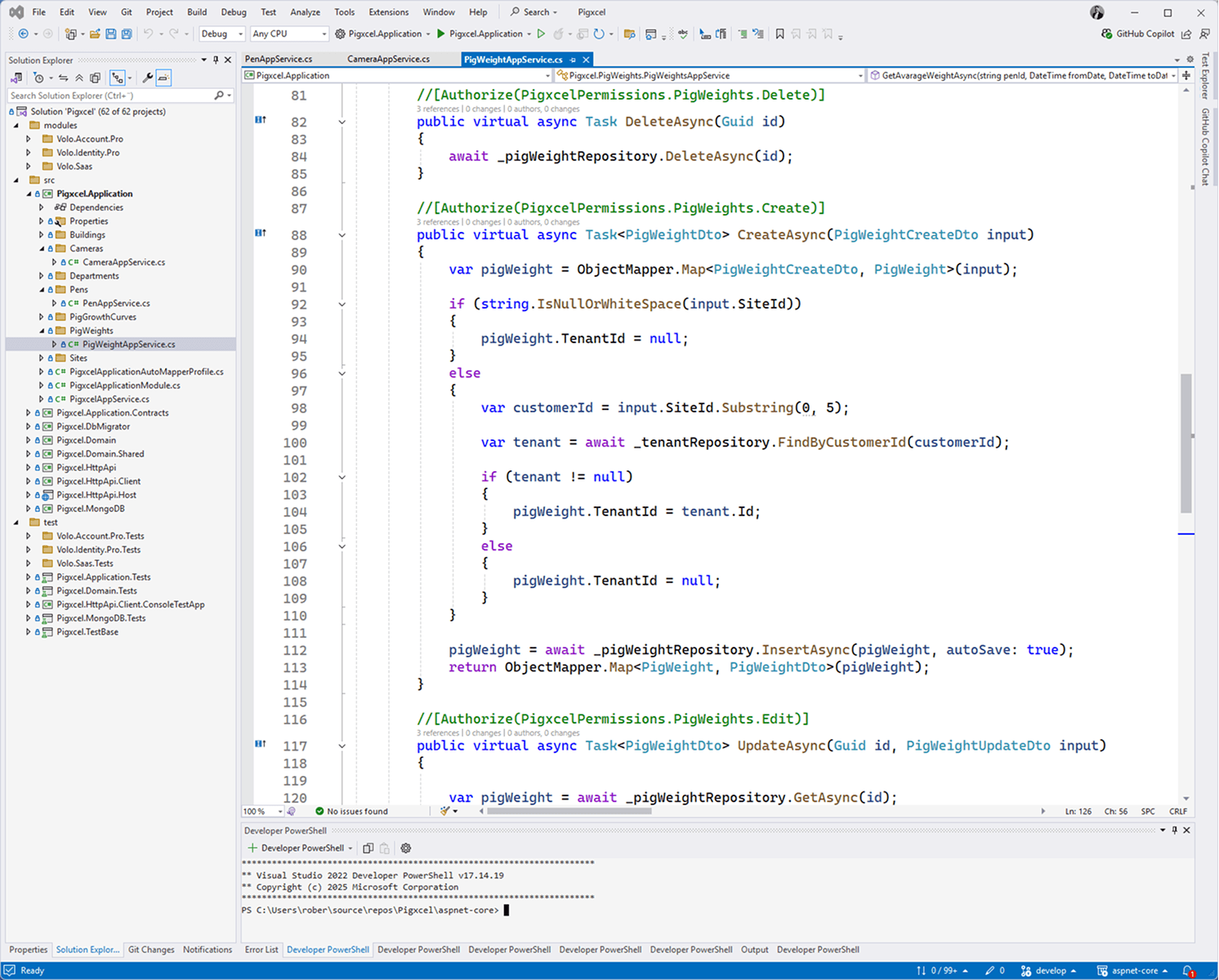

Activator built Pigxcel using Angular on the front end, ASP.NET Core Web API on the backend, and MongoDB for NoSQL data storage, all hosted on scalable Azure infrastructure. With ABP Framework’s multi-tenant architecture, the team quickly delivered a solution that supports multiple customers while scaling both vertically and horizontally as adoption grows across regions. Resource management became more efficient, and the platform delivered a seamless experience for all tenants.

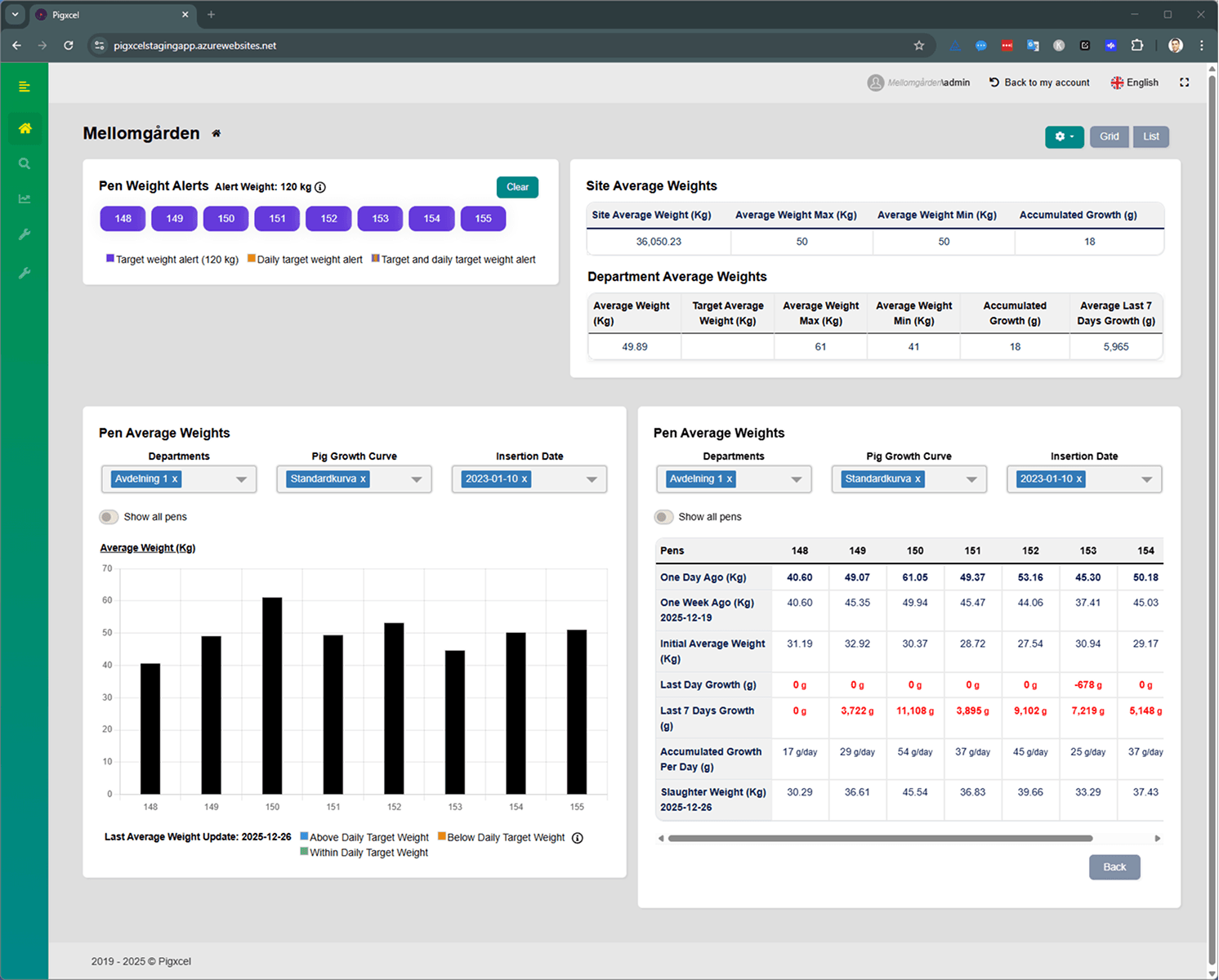

Pigxcel enables pig producers to improve accuracy in reaching target slaughter weight, reduce animal stress, and minimize feed waste. By automating previously manual tracking tasks, the system saves time and resources while enabling easy report generation, notification management, and continuous growth monitoring. Producers can take corrective actions quickly, leading to reduced manual workload, improved animal welfare metrics, optimized feed conversion, and higher operational efficiency in farm management.